The Figure #14S is for hot or cold water branch lines on gravity feed or constant pressure to 160 psi and reduces supply pressure to the desired service pressure. The adequate discharge service pressure is generally 60-65 psi. Uniform water supply at constant reduced pressure on every floor is assured with this ideal valve for High Rise buildings e.g. hotels, hospitals, apartments and offices.

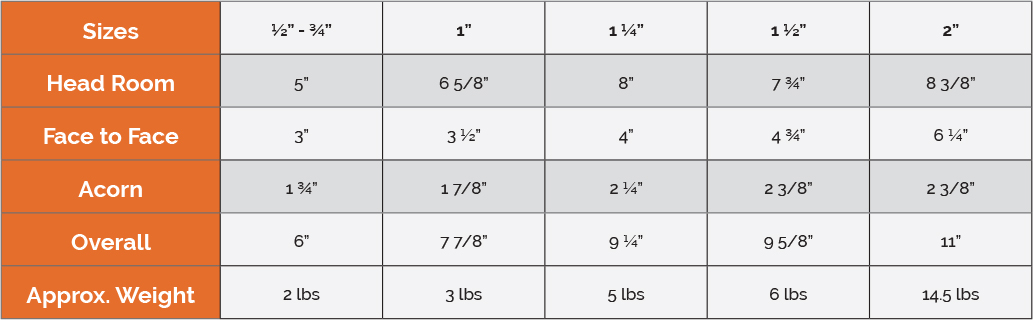

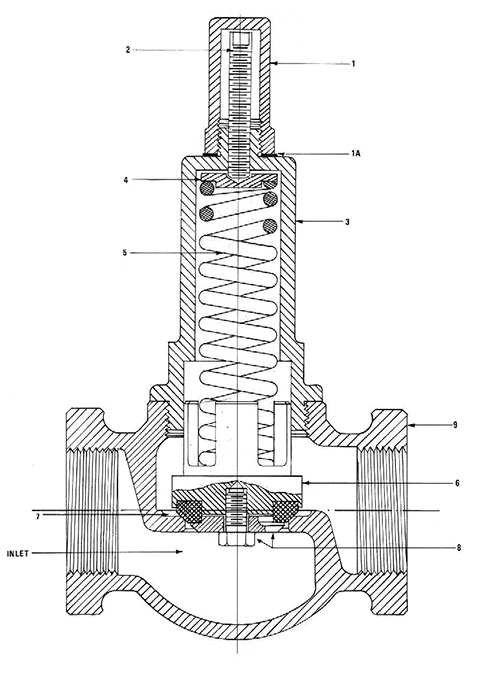

The Figure #14S is made in bronze and brass composition in sizes 1/2" to 2" inclusive in screwed pattern only. It is a single seated, piston type, spring actuated valve, without diaphragms. Our innovation of the split sleeve piston is another FORD first and serves a twofold purpose: First, it assures maximum flow of water. Secondly, it reduces the build of foreign deposits which cause binding of the piston sleeve in the bonnet. The split sleeve offers more wash away space. There is nothing to wear out which might cause leaks and resultant damage to walls, ceilings, furniture, equipment, etc. In fact, it is a non-leakable valve which has no opening to the atmosphere. This completely dependable pressure reducing valve can be installed within the walls. The pressure adjusting screw is protected by the acorn which houses it.

With the demand for water at a fixture, the velocity increases, the piston automatically opens to a wider position. Conversely, the piston automatically closes when the demand for water ceases. This valve gives controlled pressure together with adequate volume at all times. The discharge service pressure is regulated by the pressure adjusting screw: to reduce pressure – turn the adjusting screw further into the valve, and to increase discharge pressure, turn the adjusting screw out of the valve. This valve holds dead end pressure.

Manufactured by

Brooklyn, N.Y.

Size: ½” – 2” Fig. #14S